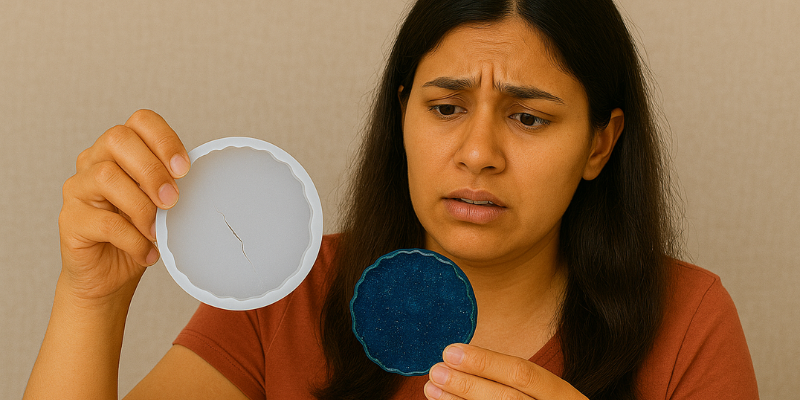

هل تعلم تلك النوبة القلبية البسيطة عندما تُفكّ أخيرًا قالب قطعة الراتنج بعد ساعات (أو أيام) من الانتظار... وارقد في سلام! يتمزق القالب، ويعلق تصميمك جزئيًا، وتفارق روحك جسدك لثانيتين.

يبدو فن الراتنج براقًا على منشورات إنستغرام، لكن وراء كل قاعدة أكواب أو سلسلة مفاتيح مثالية، يكمن مبدعٌ صرخ بصمت: "يا إلهي، أين أنت؟". إذا كنتَ قد زرتَ هذا المكان، فمرحبًا بك في النادي. وإن لم تكن كذلك، فابق معنا، ستشكرنا لاحقًا.

دعونا نكشف سبب تمزق قوالب الراتنج الخاصة بك (نعم، هناك أسباب علمية قوية)، والأهم من ذلك، كيف يمكنك التوقف عن تقطيع قوالبك الرديئة في المستقبل.

الأسباب الحقيقية وراء تمزقات قوالب الراتينج

لا نلوم "سوء الحظ" دائمًا. لا يتمزق قالبك لأنه يكرهك، بل عادةً ما يكون أحد هؤلاء الأشرار هو المتحكم:

1. متلازمة العفن القديم (OMS، إذا كنت تريد أن تبدو أنيقًا)

قوالب السيليكون تتقدم في العمر، كأي شيء آخر. مع كل استخدام، تقل مرونتها. تتراكم التمزقات الدقيقة، وتنخفض مرونتها، وفي يومٍ ما، تنهار. لا يُمكنك أن تتوقع من قالبٍ من عام ٢٠٢٠ أن يتصرف كجديدٍ في عام ٢٠٢٥. الحياة لا تسير هكذا.

2. تخطي تحرير القالب - موقف "شاليجا" الكلاسيكي

يتجاهل العديد من المبتدئين بخاخات فك القوالب، قائلين: "أيري، نيكال هي جايغا". إلى أن يحدث ذلك. الراتنج لزج بطبيعته. بدون عامل فك، يلتصق بالسيليكون بشدة. تسحب، تشد، و... تعرف ماذا يحدث بعد ذلك.

3. خطأ "أستطيع تقدير النسبة بالعين"

خلط الراتنج والمصلب ليس طبخًا جيدًا. هل لاحظتَ اختلالًا طفيفًا؟ يا إلهي! جيوب لزجة وغير مُصلبة داخل قالبك. وعندما تحاول فك القالب، تتصرف القطع اللزجة كالمُصَبّب، مُمزّقةً القالب.

4. مبالغة مسدس الحرارة

مسدسات الحرارة والمصابيح اليدوية رائعة لفرقعة الفقاعات. ولكن إذا بالغت في محاولة جعلها "شفافة تمامًا"، فقد يؤدي ذلك إلى ارتفاع درجة حرارة القالب نفسه. فالحرارة الزائدة تُضعف السيليكون بمرور الوقت، مما يجعله عرضة للتمزق في المستقبل.

5. قالب رخيص = خطأ باهظ الثمن

قوالبك هي أساس فنك. هل تلك القوالب العشوائية من متجر إنستغرام، المصنوعة للشوكولاتة أو الصابون؟ ليست آمنة دائمًا للراتنج. القوالب دون المستوى المطلوب لا تتحمل تفاعلات الراتنج الطاردة للحرارة، وتفشل بعد بضع سكبات فقط.

كيفية منع تمزق قالب الراتينج (وإنقاذ عقلك)

بعد أن كشفنا عن مُسببي المشكلة، لنبدأ العمل. الوقاية، في الواقع، أسهل بكثير (وأرخص) من استبدال القوالب الممزقة كل أسبوعين.

1. استثمر في قوالب عالية الجودة آمنة على الراتينج

ابدأ بقوالب جيدة منذ البداية. قد تكون قوالب السيليكون الاحترافية المصممة للراتنج أغلى قليلاً، لكنها تدوم لفترة أطول، وتتحمل الحرارة بشكل أفضل، وتتمتع بمرونة رائعة أثناء فك القالب.

2. لا تتجاهل إطلاق القالب أبدًا (حتى في حالة القوالب الصغيرة)

طبقة خفيفة من رذاذ فك القالب = فك قالب سلس + عمر افتراضي أطول. يشبه الأمر دهن قالب الدوسا بالزيت. يمكنك الاستغناء عنه، ولكن لماذا؟

٣. احترم النسبة دائمًا.

لا تُقدّر القياسات بالعين المجردة. استخدم ميزانًا أو كوبًا قياسًا مناسبًا. اخلط جيدًا، مع كشط الجوانب والقاع. الخلط غير الكامل يعني تصلبًا غير متساوٍ، ويلتصق الراتنج في أماكن غير مناسبة.

4. حرارة خفيفة فقط

مرري شعلتك أو مسدس الحرارة برفق فوق السطح ، وليس على بُعد بوصات قليلة كما لو كنتِ تحمّرين أعشاب من الفصيلة الخبازية. السيليكون يكره الحرارة لفترة طويلة .

5. قم بتدوير القوالب الخاصة بك

إذا كنت تقوم بطلبات كبيرة أو صبّ بانتظام ، فامنح قالبك بعض أيام الراحة. استخدام قالب واحد باستمرار يُقلّل من عمره الافتراضي .

6. التنظيف والتخزين بشكل صحيح

بعد إزالة القالب ، اغسل القالب برفق شديد بصابون لطيف وماء دافئ. خزّنه في مكان مستوٍ بعيدًا عن من أشعة الشمس، خالية من الغبار. اعتنِ بقوالبكِ كما لو كانت ساريكِ الثمين أو كورتاكِ المثالية لحفلات الزفاف.

الخلاصة: لأنه لا يستحق أي فنان أن يبكي عند ديمولدينج

لنكن صريحين، لا شيء يُفسد مزاجك مثل قالب ممزق. يُفترض أن يكون فن الراتنج علاجيًا، لا مؤلمًا. بمجرد أن تبدأ باتباع هذه القواعد البسيطة، ستلاحظ كم أصبح فك القالب سهلًا وسلسًا وخاليًا من أي تعقيدات.

وإذا كنت تتساءل أين تجد قوالب وأدوات راتنج عالية الجودة تُسهّل رحلتك الفنية، فهذا هو بالضبط سبب وجود تولسي ريسين . لقد رأينا جميع أخطاء الراتنج، لذا لا داعي لتكرارها.

صب سعيد، وإزالة سعيدة للقالب، وصفر دموع!

راتنج الأشعة فوق البنفسجية: ما هو وكيفية استخدامه في مشاريعك المنزلية

هل تتغير الألوان بعد صب الراتنج؟ نصائح للحفاظ على دقة الألوان